Modules

Flexible and modular, PRODAC delivers full customizability … enabling customers to utilize their existing solutions and to purchase only those PRODAC modules that are required to complete their systems.

At PRODAC’s core isa Real-Time Data Collection Engine and Database that collects and stores data from machine and human input. Exceptionally robust, the state-of-the-art system can collect data automatically, semi-automatically or manually – according to customer requirements.

The Basic PRODAC Package:

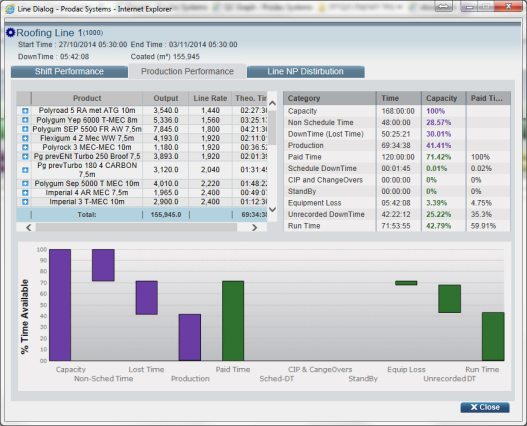

– Plant Information Center (PIC) – Provides convenient dashboard with real-time graphic

display and management data entry for entire plant; allows overall control of all PRODAC modules;

shows the entire plant at a glance; enables drill-down to detailed information, including production, downtime,

and reasons for delays.

– KPI Dashboard – Provides concise real-time information about current productivity

– Graphic Queries – Provides graphic display and management of plant-wide production history; enables reconstruction of

entire production history of he plant – or of any line or monitored facility; allows scrolling backward through time to any

date, and zooming in for details; enables various parameter combinations and cross sections over different time periods,

and comparison between planned and actual performance

– Report Generator – Generates customizable production and maintenance reports , covering all aspects of production,

including throughputs, performance, machine down time, and QC history

– Scheduler – Enables planning and scheduling of production runs; allows integration of planning and scheduling to track

performance; allocates products, packaging and personnel to production orders, runs and shifts on multiple lines,

according to customized time and raw material data; allows scheduling by quantity or time

– Line Supervisor – Enables data entry, including product changeover reports, changes in plan, use of segments, and

downtime reasons; monitors and displays efficiency, line utilization and exceptions

– Alarm-Generates alarms for faults, deviations, stoppages, QC problems, and raw materials –according to

customized settings; monitors and displays alarms; can be viewed and managed by anyone with user rights

– QC Manager – Enables complete automated quality control management, integrated with product data; provides

real-time and historical displays of quality-related data; generates sophisticated ISO-compliant automatic and manual

Quality Control recording and reporting with input either directly from measurements collected automatically

by the PRODAC data collection system, from manual data entry, or imported from laboratory equipment; includes

analyses of deviations; can correlate with downtime events

– Tank Monitoring – Monitors levels of liquid ingredients such as syrups, and connections between liquid storage tanks

and the production line – for batch preparation of liquids; display can be sorted by tank, flavor, status or priority

– Run Manager – Allows manual correction of run records

– Raw Materials – Monitors raw materials inventory; allows tracking of utilization; calculates yields; produces bills

of lading; enables both manual and automatic input

Benefits:

– State-of-the-art MES/EMI solution, specially designed for filling and packaging plants

– Fully interoperable with enterprise business systems; aligns manufacturing with business processes

– Supports lean manufacturing and OEE (Overall Equipment Effectiveness)

– Modular, scalable, upgradeable, easily integrated; optional purchase of single component to end-to-end,

enterprise-wide integrated system

– Configurable and customizable

– Supports real-time supply chain management, enterprise-wide plant floor visibility, and full collaboration

– Supports tracking and traceability

– Provides view of plant at a glance via convenient dashboard

– Generates customized reports

– Accelerates ROI, decreases TCO

– Enables optimized efficiency and production performance

– Conserves energy, minimizes spoilage, reduces inventory costs, improves scheduling, limits recalls

– Enables rapid market responsiveness, fast time-to-market

– Ensures consistent quality, regulatory compliance

– Supports fast and accurate real-time analysis and decision-making

– Delivers insights into how products flow through the plant, controls flow between machines

– Monitors downtime and reasons

– Provides real-time alerts for faults, stoppages, QC and raw material alarms

– Compares plans with performance

– Calculates resources and constraints, quantities based on rates and duration

– Recreates production history

– Valuable for all employees, including top management, plant managers, line supervisors, etc.

– Role-based solution enables pre-configuration of screens according to roles

PRODAC’s Solution for SAP® Business One

PRODAC Systems has integrated SAP® Business One with PRODAC’s MES system to create an …

end-to-end, automated, fully integrated, off-the-shelf

business and production management solution

for small and medium-sized packaging plants

PRODAC’s solution for SAP® Business One enables total production planning

through the integration of:

PRODAC Planning & Scheduling + PRODAC Syrup Unit + PRODAC Raw Materials Handling

with

SAP® Material Requirements Planning (MRP) + Warehouse Management

Benefits:

End-to-end solution- Automates and streamlines all critical business and production management processes via a single integrated system

Instant access to information- Provides total ongoing, real-time visibility of finance, production, and sales information

Automatic alerts and responses to key events – Enables management by exception; monitors, alerts, and takes action in response to specified events

User empowerment – Allows full customization by employees – including forms, policies, queries, and reports … with no need for special training

Immediate benefits – Windows environment and simplified features ease learning, operation and maintenance; rapid ROI ensured by built-in savings features

Interoperable – Easily integrated with existing applications

Materials Requirements Planning (MRP) – Simple management of MRP; enables planning scenarios and demand predictions based on forecasts; integrates MRP with scheduling

Warehouse Management – Handles inventories, item management, price lists, special price agreements, transfers between warehouses, and stock transactions

Accounting – Handles all financial transactions – including general ledger, account setup and maintenance, journal entries, foreign currency adjustments, and budgets

Bank Transactions – Handles all financial processing – including cash receipts, check writing, deposits, advance payments, credit card payments, and bank reconciliation

Sales and Delivery – Enables price quotes, order entries, delivery scheduling, stock updates, and management of invoices and accounts receivables

Purchasing – Manages and maintains vendor contracts and transactions

Sales Opportunity Management – Records sales opportunities from first contact to close of transaction

Business Partner Management – Controls all information about customers, resellers, and vendors

Service Management – Handles service operations, contract management, service planning, tracking of customer interactions, and customer support

Reports – Generates a wide range of detailed reports